VIRIDYN 101-X

HYDROPHOBIC, OLEOPHOBIC, ULTRA-THIN

VIRIDYN 101-X is a hydrophobic and oleophobic nano-coating used to protect electronics and fluidic devices from water, biofluids, oils, and similar exposures.

Application methods: Easily applied by dip, spray, spin, flow, or syringe coating. Masking not required when VIRIDYN 101-X concentrations of less than 4% are used. Dries quickly at room temperature.

Color: Transparent

Water contact angle: over 105°

Mineral oil contact angle: over 60°

Key Features & Benefits

Hydrophobic & Oleophobic: Repels both water and oils, achieving an oleophobicity grade of up to 8.

Acrylic-Based Polymer: Provides durable and flexible protection.

Low Viscosity & Surface Tension: Ensures even coating and penetration into small features.

Transparent Coating: Maintains visibility of underlying components. UV tracer compatible for ease of quality control inspections.

Customizable Concentrations: Available in 0.2% to 10% polymer solutions in various solvents.

Corrosion & Damage Protection: Prevents corrosion, sweat damage, tin whiskers, and dendrites.

Salt-Fog Resistance: Protects critical electronics in high-stress harsh environments.

RF-Transparent: at 2 microns or less.

All ViriDyn conformal coatings are low toxicity, non-ozone depleting and RoHS compliant. ViriDyn conformal coatings are available with flammable and non-flammable solvent components.

Major Applications

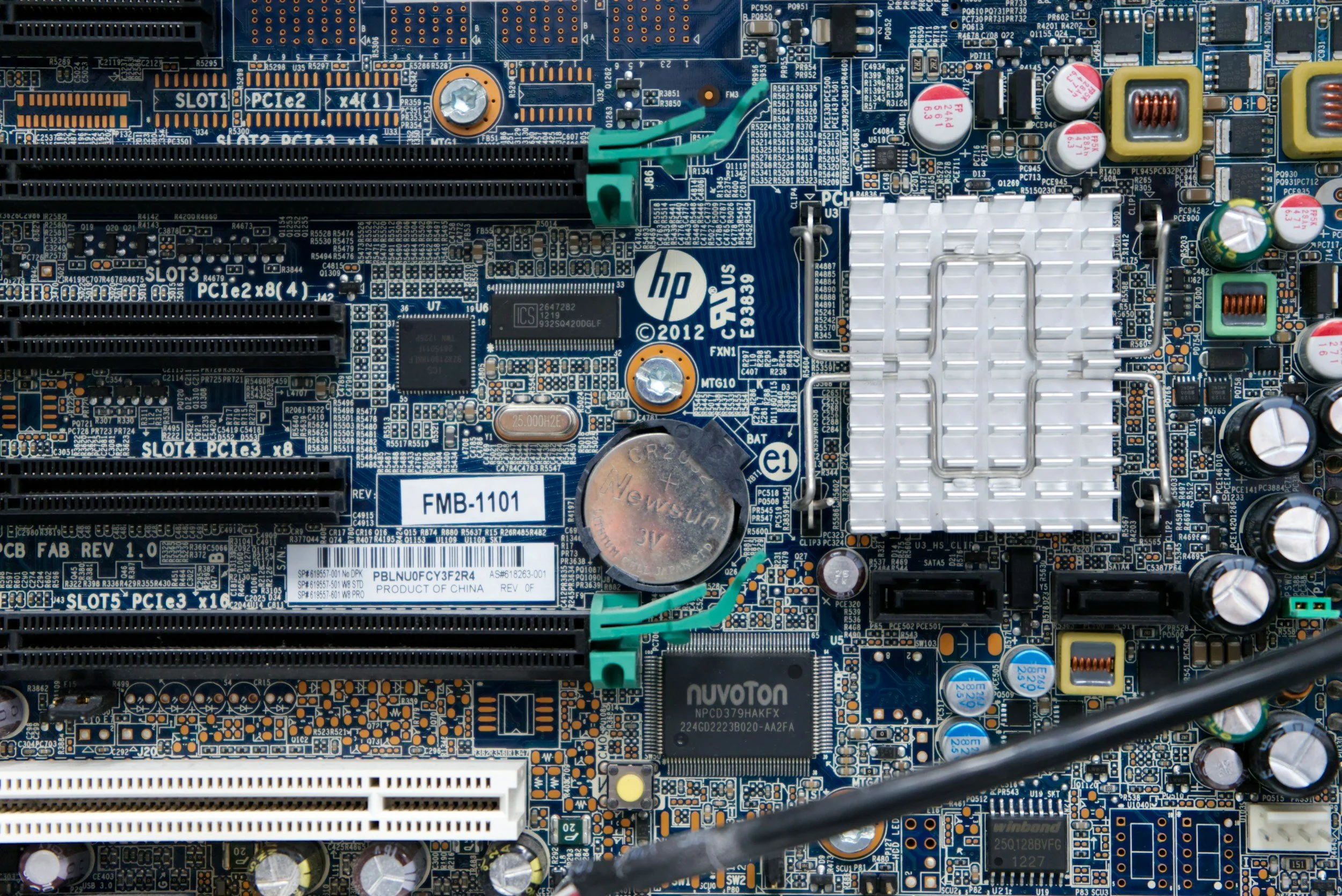

Electronics Protection: Ideal for printed circuit boards, ball-grid arrays, micro-motors, MEMS, and hard disk drive components.

Laboratory & Medical Devices: Used for coating plastic laboratory devices and microfluidic devices.

Precision Components: Suitable for MR heads and other sensitive electronic parts.

Novec™ Replacements: Coatings derived from the 101-X family are excellent replacements for Novec™ 1700 series and Novec™ 1900 series electronic grade coatings. PFAS-free alternatives are also available. All ViriDyn Novec™ replacements are RoHS and REACH compliant.

-

Application method: Brush, dip, selective dispense, spray, etc.

Applications: Anti-Stiction, chemical protection, corrosion protection, moisture protection

Coating thickness: 0.3 µm - 0.6 µm (at 4% concentration)

Dry time: 30 - 120 seconds (no cure needed)

Uses: printed circuit boards (PCB), solder joint, ball grid arrays, printer heads, semiconductor photomasks, and other electronic components

Properties: Repels oils, water, hydrocarbons, silicones, photoresists

Solids percent: 0.2, 1, 2, 4, 8, or 10%

Temperature range max: 175⁰C

Flammability: UL94 V-0

Moisture resistance: ~1 x 1012 Ω

Surface energy: 15 dynes/cm

Dielectric constant: 2.9 (at 1kHz, 30% relative humidity)

Dielectric strength: ~2800 V/mil

Surface insulation resistance: 1 x 10^15 Ω

Dissipation factor: 0.016 @ 1MHz

Water contact angle: 105⁰

Package options: 3 LBS (liter bottle), 10 LBS (gallon bottle), 60 LBS (6-gallon carboy)